The main structure of the ore is Pyrolusite (MnO2) and since it does not have a complex structure, we produce 2000-2500 tons of concentrated Manganese per month with high grade and 0-5mm size in the aqueous enrichment process with jig. In our facility, we easily produce high grade Manganese and Manganese Dioxide (MnO2) with minimal impurities and appropriate ratios.

The concentrated Manganese product we produce has a high density, low silica structure and can be easily crushed and ground. Since its ratio is high, it has been observed that it is suitable for easy dissolution and melting. The manganese concentrate produced is predominantly Manganese Dioxide as the major oxide. The total of minor oxides does not take up much space and is low.

We developed as a result of our studies on manganese concentrate production;

-We produce throughout the year with enrichment systems suitable for our ore.

-We produce concentrated manganese non-stop despite seasonal conditions.

-We produce according to domestic or international demands and usage areas throughout the year.

-We produce concentrates with different grades to meet the demands of battery, metal-metallurgy, iron-steel, casting, ferromanganese, premix feed producers, fertilizer and chemical markets.

For continuous quality monitoring in our enrichment facility;

-We have a sample preparation and Analytical Chemistry laboratory.

-Production of high grade concentrated Manganese and Manganese Dioxide with manganometric, titrimetric and gravmetric analyzes performed in our laboratory; ∑Mn, MnO2, Fe, FeO, SiO2 are constantly monitored with LOI analyses.

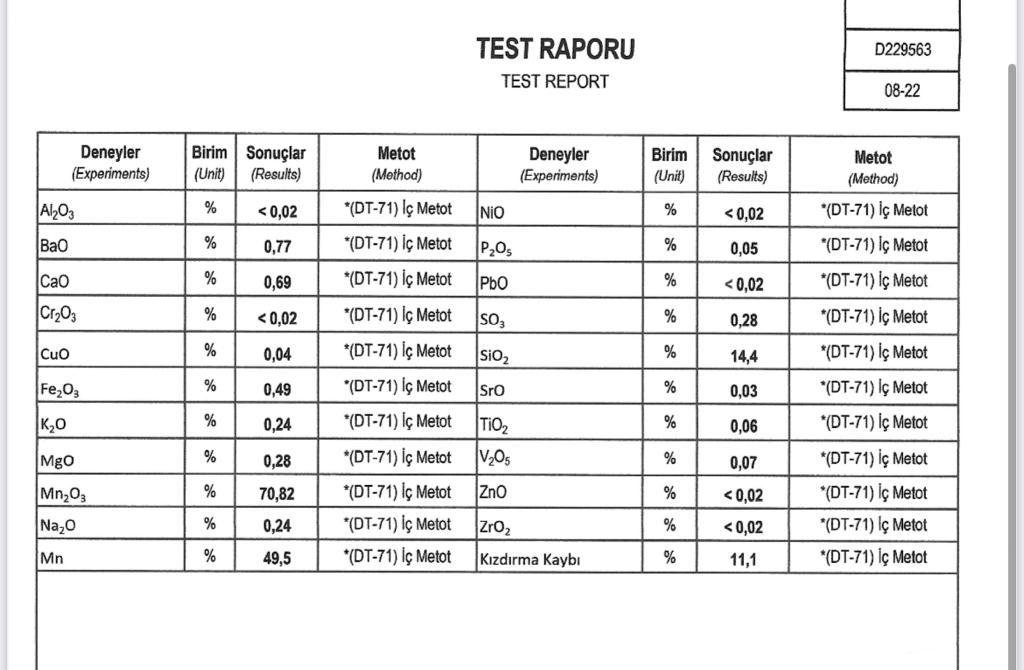

-The analysis specifications of the concentrate we produce in our in-house chemistry laboratory and external laboratories are as follows;

52-58 ∑ Mn %80-88 MnO2 9-10 LOI(KK)

6-7 SiO2 d=3,5-4 kg/lt Minor oxides <%3

Usage areas of the concentrated Manganese we produce;

*It is consumed as ferromanganese and silicomanganese as the most important alloys of iron in the iron, steel and metallurgical industries.

*It is used as a catalyst in the glass industry, disinfectant, fertilizer, ceramics, refractories and chemistry.

* Manganese derivatives are important in electric vehicle batteries and energy storage. Today, Mn is used in high-performance rechargeable lithium-ion battery technology (nickel cobalt manganese-NCM) in the automotive industry, especially in factories producing electric cars in Europe and America. Increasing electric car production in the world will further increase the demand for manganese ore.

*Especially manganese sulfate (MnSO4), sodium and potassium permanganate are involved in many chemical processes. As a strong oxidizer, it is used in quantitative analyzes and in the field of medicine, in drinking water and wastewater treatment systems, in agriculture to nourish the soil and as an insecticide to prevent harmful fungi in fruit trees, and as an additive in auto paints and the feed industry.

*It is used as manganese phosphate in coating processes, special coatings, military weapons industry coatings, gear and transmission parts coatings.

As a successful company in the mining industry, we have completed our preparations and studies for all kinds of Manganese derivatives used in the industry and the manganese forms that will take their place in lithium ion battery technology.

Manganese Test Report