The most important differences of our bentonit deposits compared to others.

- Swelling Capacity: Bentonite has a unique property called “swelling” or “hydration,” where its volume increases significantly when it comes into contact with water. This swelling ability is important for applications such as drilling muds, where it helps control pressure and lubrication in oil and gas drilling.

- Thixotropic Behavior: Thixotropy refers to the property of certain materials to become less viscous (more fluid) when agitated and return to their original viscosity when left undisturbed. Quality bentonite can exhibit thixotropic behavior, which is valuable in applications like paints, coatings, and drilling muds, as it provides stability during storage and easy application when needed.

- Cation Exchange Capacity (CEC): Bentonite has a high cation exchange capacity, which means it can hold and exchange positively charged ions (cations) with the surrounding environment. This property is essential in soil improvement, agriculture, and environmental remediation, where bentonite can absorb and release nutrients, pollutants, and contaminants.

- Colloidal and Rheological Properties: Bentonite forms stable colloidal suspensions when mixed with water. It has a high surface area and can maintain a stable suspension due to its electrostatic charges. This property is valuable in applications such as drilling muds, foundry casting, and as a binding agent in ceramics.

- Binding and Adsorption: Bentonite has strong binding and adsorption capabilities. This makes it useful in industries like foundry and pelletizing, where it’s used to bind particles together, as well as in wastewater treatment to adsorb impurities.

- Chemical Stability: Quality bentonite should be chemically stable under a wide range of conditions. It should not undergo significant changes in its properties when exposed to varying pH levels, temperature fluctuations, or different chemical environments.

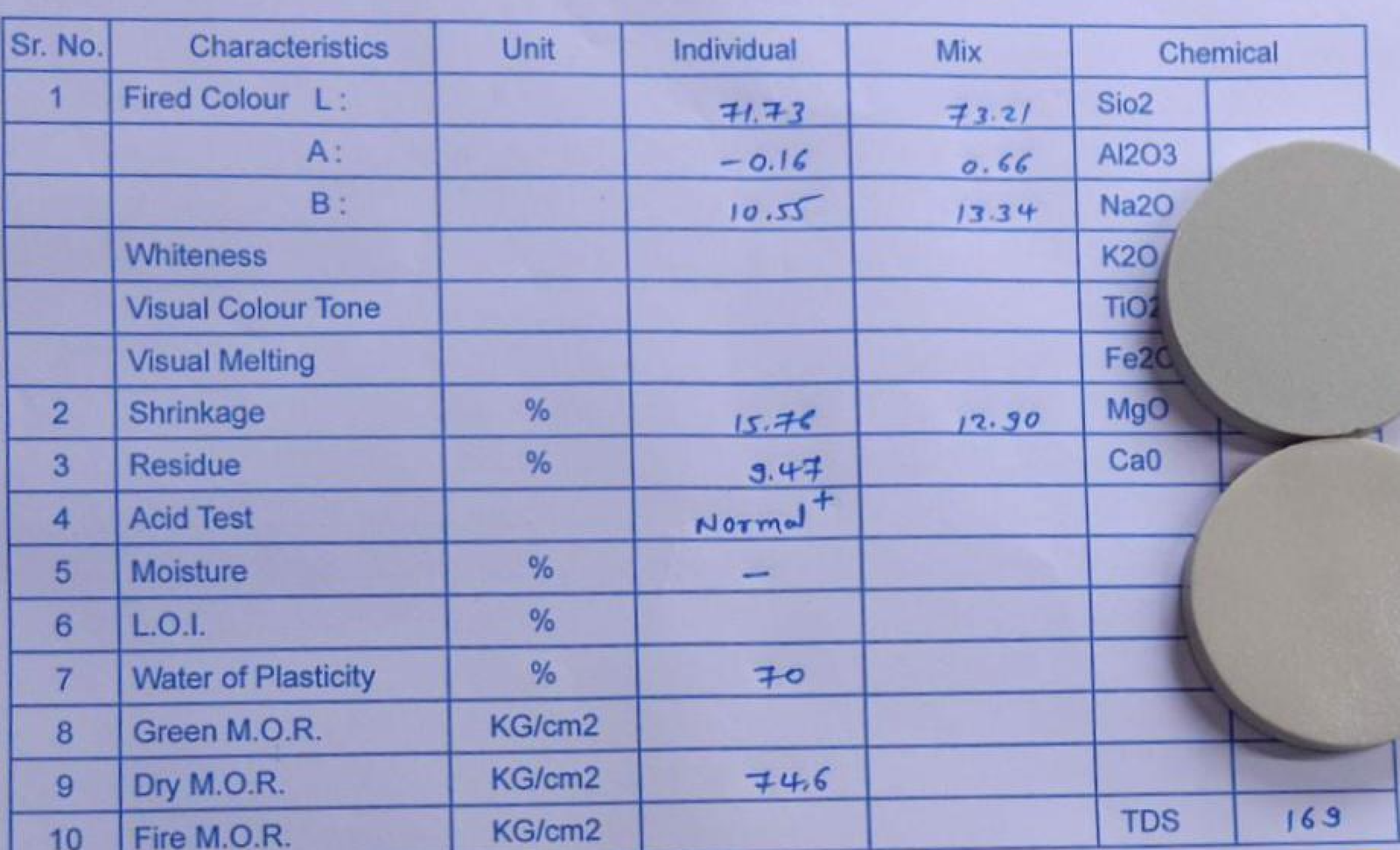

- Low Residue: In some applications, particularly in drilling fluids and cosmetics, having minimal impurities and low residue content is crucial to ensure consistent performance and avoid unwanted side effects.

- Particle Size Distribution: The particle size distribution of bentonite can influence its performance in various applications. Different particle sizes may be more suitable for specific uses, such as enhancing viscosity or controlling fluid loss.

- Purity: High-quality bentonite should have a high degree of purity, without significant amounts of impurities or contaminants that could negatively impact its intended applications.

- Availability: Bentonite should be readily available in sufficient quantities and consistent quality to meet the demands of various industries.

Whiteness

The values of the minerals we extract are suitable for many industrial uses and we have regular exports to dozens of countries.

Purity

We do not leave quality to chance by analyzing our products not only in our own laboratories but also in other accredited laboratories.

Productivity

Thanks to our regular exports and high business volume, we offer you the best shipping prices and the fastest delivery options.